Our production process at Hinscha

At Hinscha, we attach great importance to transparency and quality. We are therefore pleased to give you insight into the meticulous production process behind our high-quality hinges.

Thorough planning and careful material selection

Each hinge we produce begins with a well-thought-out production plan, ensuring each phase runs efficiently and all parts are delivered on time. We carefully select the necessary materials and ensure they are precisely cut to size. After cutting, the parts undergo a tumbling and drying process, preparing them for further processing.

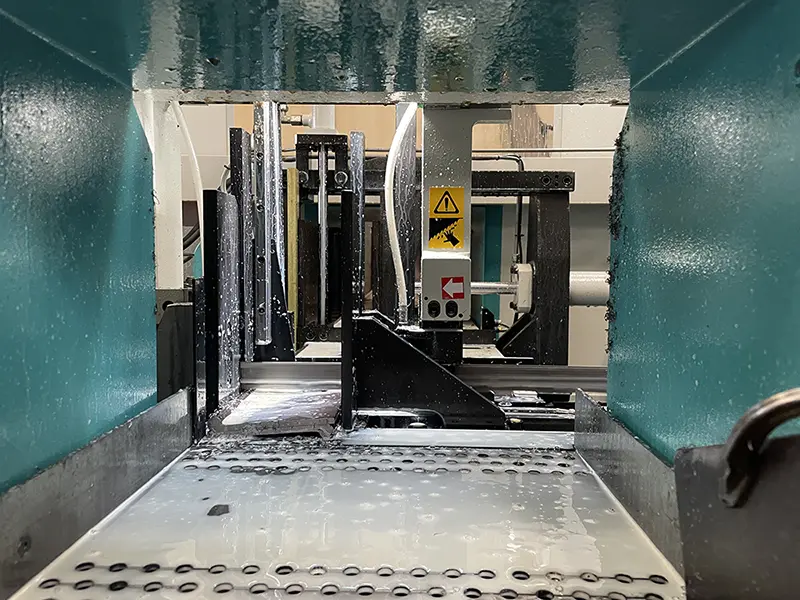

Precision in shaping hinges

Following tumbling and drying, the parts are placed in our CNC and milling machines, where the necessary holes and indentations are accurately created. To further ensure quality, we tumble and dry the parts again to remove any sharp edges or irregularities. If needed, the hinges are then bent and coated with an extra protective layer through galvanizing or painting. The final step is the assembly of the pin or grease nipple, a crucial component for the hinge’s functionality.

Careful packaging or storage

After completing the production process, the hinges are carefully packaged and shipped to the customer, or stored in our warehouse. This meticulous approach ensures that each hinge not only meets but exceeds your expectations.

We invite you to explore our products and experience the quality of our hinges for yourself.

Hinscha: your partner for standard and custom hinges

At Hinscha, we specialize in both standard and custom hinge solutions. Using the latest techniques in our hinge factory, we can produce both small and large hinge series. Do you have specific requirements for your hinges? Our flexible organization allows us to quickly create prototypes based on your own design or in collaboration with our hinge experts.

We are happy to share our years of expertise with you to help you select the right hinge type, matched to the strength class required for your construction.

Did you know that as much as 40% of all hinges are not properly dimensioned due to a lack of knowledge? At Hinscha, we ensure that your design receives optimal support.

Framework agreements for your hinge requirements

Do you need a large quantity of hinges, possibly spread over an extended period? At Hinscha, you can enter into a framework agreement. This tailored contract guarantees delivery at pre-agreed prices and conditions. Framework agreements are particularly popular with car manufacturers, truck and cabin builders, machinery manufacturers, and the construction industry, as they anticipate price fluctuations and provide shorter delivery times.

At Hinscha, we say: if you can imagine it, we can make it. And if you can't imagine it, we’re here to help.