Bespoke Hinges

Do you need a special or specific custom hinge? Hinscha is here to help you with your challenge. We will work together to deliver the ideal hinge. Discover some of our beautiful realisations beneath.

Custom-made Coach Hinges

Our Hinscha coach hinges are made from hot-rolled profiles. Coach hinges are extremely strong and have tight tolerances. By default, our coach hinges are used for welding, but holes can also be provided to secure the hinge with screws.

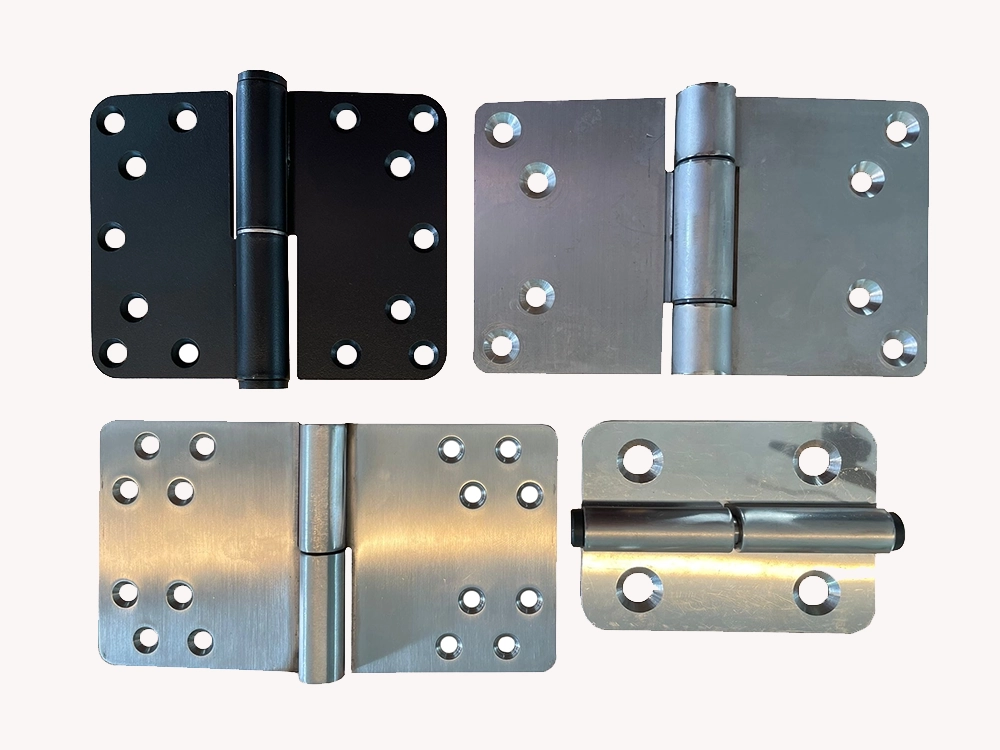

Custom-Made Rolled Hinges

Rolled hinges are manufactured using a stamping process. The metal is shaped to form a knuckle. Both hinge halves are then carefully calibrated to ensure a perfect fit and the correct pin diameter.

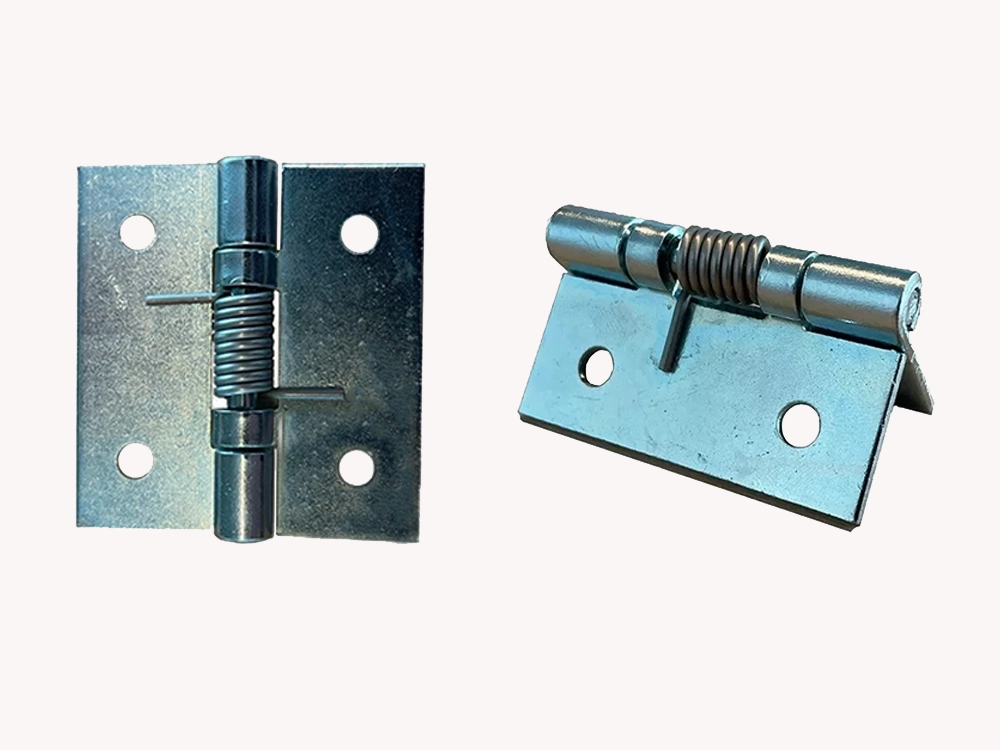

Spring Hinges

Spring hinges are custom-made hinges equipped with a spiral spring. Depending on your specific challenge, the spring force is calculated, and if necessary, an alternative type of spring can be used.

Need a custom hinge?

Get in touch with our technical account manager today. Pascal will gladly assist you in finding an efficient, tailor-made solution.

Years of Expertise

At Hinscha, we take pride in our expertise in manufacturing bespoke hinges. When our standard hinges are not suitable for your application, we are ready to produce a customer-specific hinge, based on a technical drawing or after a thorough consultation with one of our expert sales reps.

In need of large or small series? Hinscha is the perfect partner for you.

ISO 9001

Optimization, efficiency, and standardization have been in Hinscha's DNA from the beginning. In 2021, we went a step further: supported by an external consultancy firm, we achieved the ISO 9001:2015 certification on August 10, 2021, for the production and delivery of profile hinges and the supply of industrial parts to companies. This ensures that our quality management system meets the applicable ISO quality requirements and that our customers can always rely on quality throughout all layers of the company.